208-230/460/3

Whaley typically keeps these capacities in stock in packaged units with pumps and reservoirs. Whaley packaged chillers utilize high efficient R-410a refrigerant which can be 5-10% more efficient than its’ predecessor R-22. Whaley Chillers can operate in any ambient climate. Chillers can be equipped with low ambient crankcase heaters and fan cycling switches to ensure proper performance and safety when installed in northern cold climates. |

208-230/460/3 Dual Circuit 10 Ton – 20 Ton

|

Model #

|

Tonnage

|

KW

|

BTU/hr

|

Pumps

|

Voltage

|

Unit Amps

|

Supply Pump HP

|

Circulation Pump HP

|

GPM

|

Poly-tank size

|

| SA3-3-PT |

3 Ton

|

10.5

|

36,000

|

Single

|

208-230/3

|

15.5

|

1hp, #11

|

–

|

7.2

|

15 gal

|

| SA3-3-2PT |

3 Ton

|

10.5

|

36,000

|

Dual

|

208-230/3

|

17.7

|

1hp, #11

|

0.5hp, #69

|

7.2

|

30 gal

|

| SA3-4-PT |

3 Ton

|

10.5

|

36,000

|

Single

|

460/3

|

8.2

|

1hp, #11

|

–

|

7.2

|

15 gal

|

| SA3-4-2PT |

3 Ton

|

10.5

|

36,000

|

Dual

|

460/3

|

9.2

|

1hp, #11

|

0.5hp, #69

|

7.2

|

30 gal

|

| SA4-3-PT |

4 Ton

|

14

|

48,000

|

Single

|

208-230/3

|

19.4

|

1hp, #11

|

–

|

9.6

|

30 gal

|

| SA4-3-2PT |

4 Ton

|

14

|

48,000

|

Dual

|

208-230/3

|

21.6

|

1hp, #11

|

0.5hp, #69

|

9.6

|

30 gal

|

| SA4-4-PT |

4 Ton

|

14

|

48,000

|

Single

|

460/3

|

9

|

1hp, #11

|

–

|

9.6

|

30 gal

|

| SA4-4-2PT |

4 Ton

|

14

|

48,000

|

Dual

|

460/3

|

10

|

1hp, #11

|

0.5hp, #69

|

9.6

|

30 gal

|

| SA5-3-PT |

5 Ton

|

17.5

|

60,000

|

Single

|

208-230/3

|

21.3

|

1hp, #11

|

–

|

12

|

30 gal

|

| SA5-3-2PT |

5 Ton

|

17.5

|

60,000

|

Dual

|

208-230/3

|

23.5

|

1hp, #11

|

0.5hp, #69

|

12

|

30 gal

|

| SA5-4-PT |

5 Ton

|

17.5

|

60,000

|

Single

|

460/3

|

10.6

|

1hp, #11

|

–

|

12

|

30 gal

|

| SA5-4-2PT |

5 Ton

|

17.5

|

60,000

|

Dual

|

460/3

|

11.6

|

1hp, #11

|

0.5hp, #69

|

12

|

30 gal

|

| SA6-3-PT |

6 Ton

|

21

|

72,000

|

Single

|

208-230/3

|

25.4

|

1hp, #11

|

–

|

14.4

|

30 gal

|

| SA6-3-2PT |

6 Ton

|

21

|

72,000

|

Dual

|

208-230/3

|

27.6

|

1hp, #11

|

0.5hp, #69

|

14.4

|

30 gal

|

| SA6-4-PT |

6 Ton

|

21

|

72,000

|

Single

|

460/3

|

12.8

|

1hp, #11

|

–

|

14.4

|

30 gal

|

| SA6-4-2PT |

6 Ton

|

21

|

72,000

|

Dual

|

460/3

|

13.8

|

1hp, #11

|

0.5hp, #69

|

14.4

|

30 gal

|

| SA7.5-3-PT |

7.5 Ton

|

26.3

|

90,000

|

Single

|

208-230/3

|

35.5

|

2hp, #126

|

–

|

18

|

30 gal

|

| SA7.5-3-2PT |

7.5 Ton

|

26.3

|

90,000

|

Dual

|

208-230/3

|

37.7

|

2hp, #126

|

0.5hp, #69

|

18

|

30 gal

|

| SA7.5-4-PT |

7.5 Ton

|

26.3

|

90,000

|

Single

|

460/3

|

17.1

|

2hp, #126

|

–

|

18

|

30 gal

|

| SA7.5-4-2PT |

7.5 Ton

|

26.3

|

90,000

|

Dual

|

460/3

|

18.1

|

2hp, #126

|

0.5hp, #69

|

18

|

30 gal

|

| SA10-3-PT |

10 Ton

|

35.1

|

120,000

|

Single

|

208-230/3

|

44.3

|

2hp, #126

|

–

|

24

|

40 gal

|

| SA10-3-2PT |

10 Ton

|

35.1

|

120,000

|

Dual

|

208-230/3

|

46.5

|

2hp, #126

|

0.5hp, #69

|

24

|

40 gal

|

| SA10-4-PT |

10 Ton

|

35.1

|

120,000

|

Single

|

460/3

|

21.6

|

2hp, #126

|

–

|

24

|

40 gal

|

| SA10-4-2PT |

10 Ton

|

35.1

|

120,000

|

Dual

|

460/3

|

22.6

|

2hp, #126

|

0.5hp, #69

|

24

|

40 gal

|

Physical Specifications

|

Model #

|

Tonnage

|

KW

|

Voltage

|

Length

|

Width

|

Height

|

# of

Compressors |

Inlet/Outlet

Connections |

| SA3-3-PT |

3 Ton

|

10.5

|

208-230/3

|

32″

|

32″

|

68″

|

1

|

1″

|

| SA3-3-2PT |

3 Ton

|

10.5

|

208-230/3

|

36″

|

36″

|

68″

|

1

|

1″

|

| SA3-4-PT |

3 Ton

|

10.5

|

460/3

|

32″

|

32″

|

68″

|

1

|

1″

|

| SA3-4-2PT |

3 Ton

|

10.5

|

460/3

|

36″

|

36″

|

68″

|

1

|

1″

|

| SA4-3-PT |

4 Ton

|

14

|

208-230/3

|

36″

|

36″

|

64″

|

1

|

1″

|

| SA4-3-2PT |

4 Ton

|

14

|

208-230/3

|

36″

|

36″

|

64″

|

1

|

1″

|

| SA4-4-PT |

4 Ton

|

14

|

460/3

|

36″

|

36″

|

64″

|

1

|

1″

|

| SA4-4-2PT |

4 Ton

|

14

|

460/3

|

36″

|

36″

|

64″

|

1

|

1″

|

| SA5-3-PT |

5 Ton

|

17.5

|

208-230/3

|

36″

|

36″

|

69-1/2″

|

1

|

1″

|

| SA5-3-2PT |

5 Ton

|

17.5

|

208-230/3

|

36″

|

36″

|

69-1/2″

|

1

|

1″

|

| SA5-4-PT |

5 Ton

|

17.5

|

460/3

|

36″

|

36″

|

69-1/2″

|

1

|

1″

|

| SA5-4-2PT |

5 Ton

|

17.5

|

460/3

|

36″

|

36″

|

69-1/2″

|

1

|

1″

|

| SA6-3-PT |

6 Ton

|

21

|

208-230/3

|

56″

|

40″

|

84″

|

1

|

1″

|

| SA6-3-2PT |

6 Ton

|

21

|

208-230/3

|

56″

|

40″

|

84″

|

1

|

1″

|

| SA6-4-PT |

6 Ton

|

21

|

460/3

|

56″

|

40″

|

84″

|

1

|

1″

|

| SA6-4-2PT |

6 Ton

|

21

|

460/3

|

56″

|

40″

|

84″

|

1

|

1″

|

| SA7.5-3-PT |

7.5 Ton

|

26.3

|

208-230/3

|

56″

|

40″

|

84″

|

1

|

1.25″

|

| SA7.5-3-2PT |

7.5 Ton

|

26.3

|

208-230/3

|

56″

|

40″

|

84″

|

1

|

1.25″

|

| SA7.5-4-PT |

7.5 Ton

|

26.3

|

460/3

|

56″

|

40″

|

84″

|

1

|

1.25″

|

| SA7.5-4-2PT |

7.5 Ton

|

26.3

|

460/3

|

56″

|

40″

|

84″

|

1

|

1.25″

|

| SA10-3-PT |

10 Ton

|

35.1

|

208-230/3

|

68″

|

44″

|

84″

|

1

|

1.25″

|

| SA10-3-2PT |

10 Ton

|

35.1

|

208-230/3

|

68″

|

44″

|

84″

|

1

|

1.25″

|

| SA10-4-PT |

10 Ton

|

35.1

|

460/3

|

68″

|

44″

|

84″

|

1

|

1.25″

|

| SA10-4-2PT |

10 Ton

|

35.1

|

460/3

|

68″

|

44″

|

84″

|

1

|

1.25″

|

Standard Features:

|

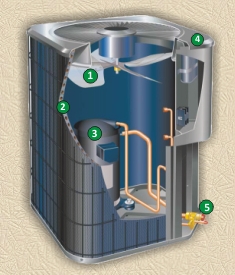

1. Condenser Fan2. Copper Tube / Enhanced Fin Coil3. High Efficiency Copeland Scroll Compressor

4. heavy Gauge Steel Cabinet 5. Refrigerant Line Connections, Electrical Inlets, & Service Valves

|

Vertical air discharge minimizes operating sounds.

TEFC motor for maximum protection from weather, dust, and corrosion.

Rain Shield on motor provides additional protection from moisture.

Ripple-edged aluminum condenser fins. Lanced fins provide maximum exposure of fin surface to air stream resulting in excellent heat transfer.

Fin collars grip tubing for maximum contact area.

Copper tube construction.

Coil is factory tested under high pressure to ensure leakproof construction.

Entire coil is accessible for simplified cleaning.

Compressor crank case heater for low ambient installations.

Copeland Scroll Compressors

Copeland compressors are utilized to provide the most efficient chiller system possible. Compa-Chill chillers credit the R-410a compressors for their reduced energy consumption, low vibration, reduced moving parts, and high resistance to liquid refrigerant return. 5 year compressor warranty is standard.

Supply Pumps

100’ TDH is standard design. Base mounted on sturdy 14 gauge steel to eliminate vibration, centrifugal iron TEFC motors are standard. For dual pump option, a smaller 40-60’ TDH recirculation pump is added to ensure proper water flow through evaporator to eliminate evaporator freeze-up. Many customers prefer this option for added security in the field.

Brazed SS Plate Heat Exchangers

A Stainless Steel 316SS is utilized to allow maximum heat exchange between refrigerant and water.

Insulated Reservoirs

Packaged units come standard with internal insulated rotomolded polypropylene reservoir for cold water storage. With dual pump option, reservoir is typically upgraded to a larger volume. to accomodate the extra flow in & out.

TXV’s, Filter Dryer, Sight Glass

Standard thermastatic expansion valves incorporate balanced port construction, which makes them ideally suited for applications with a wide range of operating conditions. Specially designed for the higher pressure associated with the high efficiency R-410a. Filter dryers and sight glasses installed in liquid line for added security and simplified maintenance.

Some Benefits of a Whaley Chiller

Energy Efficiency

R-410a is more efficient than earlier R-22 systems because the higher pressures of R-410a systems make for greater refrigerant mass flow rates through the TXV. Laboratory analysis and testing have shown that R410A allows higher heat transfer than R22, resulting in more efficient operation. So choosing a Whaley Chiller with R410A not only makes sense environmentally – it also makes sense from an economic standpoint.

Simplified Controls Equals Simplified Price

Digital Temperature Controls are utilized with easy to operate set point and temperature differential operation. The controller provides accurate temperature indication and control. Temperature is sensed from water outlet of evaporator. Available in Fahrenheit or Celsius measurement. Microprocessor control system available as option.

Chiller System Safeties

Adjustable low pressure switch, fixed high pressure switch, and head pressure fan cycling switch will all be utilized in WPI’s chiller systems ensuring the safety of system components at all times.

Evaporator Security

Dedicating a chiller circulation pump in addition to the supply pump ensures proper flow through the evaporator at all times. This eliminates the risk of freezing up an evaporator and damaging other key components in your system.

Warranty

Whaley Products offers 1 year warranty on parts and a 5 year compressor replacement warranty. This extended warranty for the compressor ensures you are getting the most of your investment with WPI.

24/7 Technical Support

Our technical support agents are available 24/7 to assist you in emergency cooling situations.